-

High Capacity - Optimized for large-scale freeze drying to accommodate significant batch sizes.

Sweet Mode - Freeze drying of sweets & candies, heating the product up to +70°C, Turbo cooling of the final product, Short (ca. 1-3 hours) & adjusted cycles.

Efficient Freeze Drying Process - Preserves nutritional content, flavours, and textures effectively.

Energy-Efficient Operation - Designed to minimize energy use while maximizing output.

Advanced Temperature Control - Precise control ensures consistent, high-quality results.

Robust Construction - Industrial-grade build for reliability in high-demand environments.

User-Friendly Interface - Simplifies complex freeze drying processes for ease of use.

-

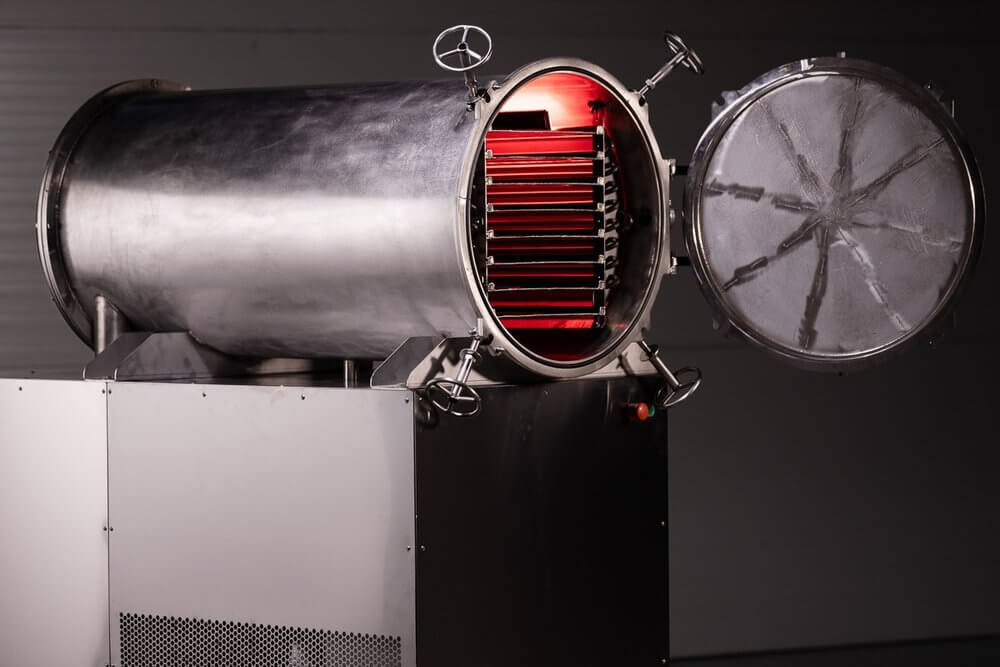

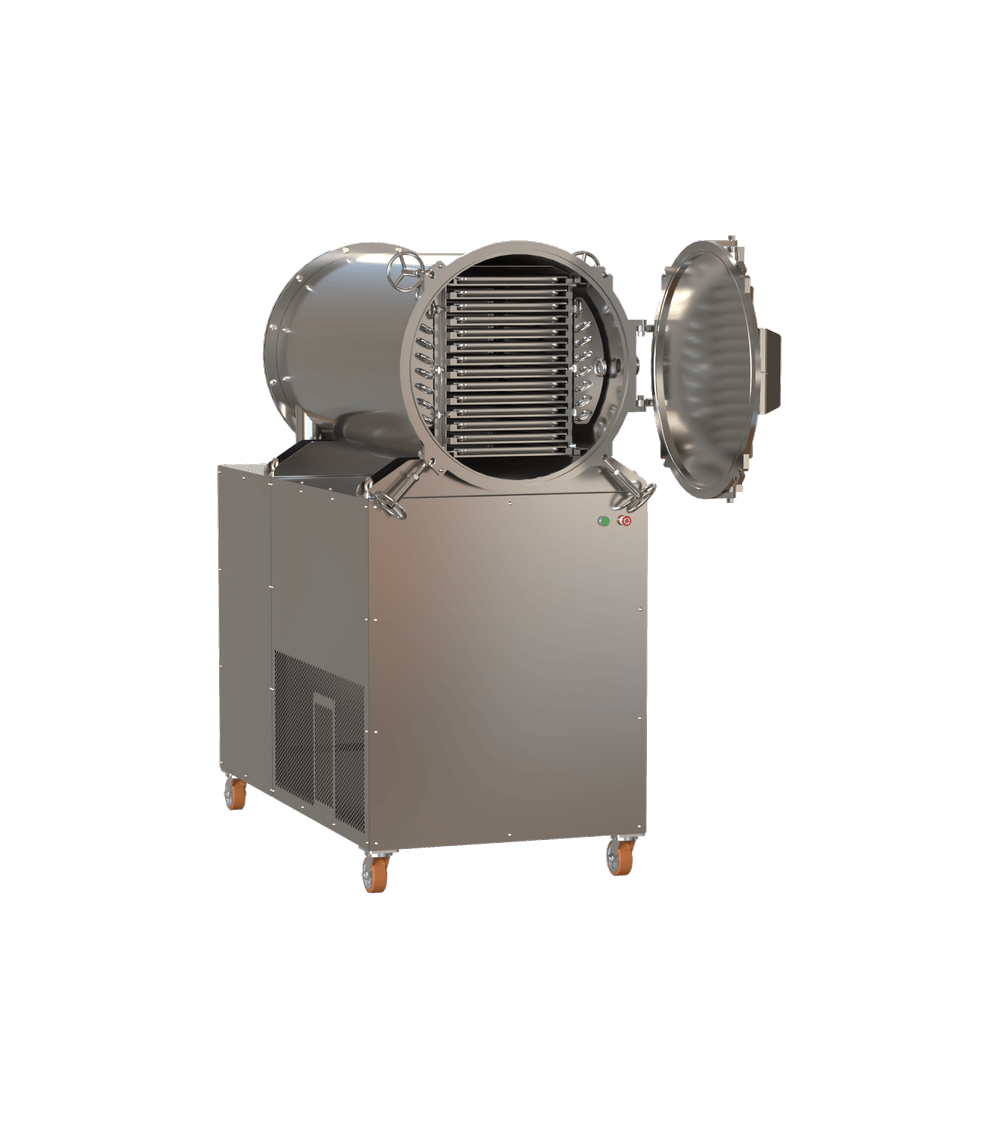

LEO-030 Freeze Dryer.

16 trays.

Drainage hose with connector.

1 litre of oil.

Spare temperature sensor.

Leosmak bag.

Operating manual.

Catalogue.

-

Dimensions: 80 cm W x 185 cm D x 180 cm H

Weight: Approx 600 kg

Capacity: 30 kg per batch

Power: 3-Phase 380V

Warranty: Minimum 24 Months.

-

Details: Please contact for shipping rates.